Home from an excellent one week holiday in

Ravenna, Italy with the family, where we among other things met

Biol and his really friendly family. One day Biol took us to meet Luigi in Reggio Emilia and we visited of course Luigi's rapidly progressing build in his huge workshop. Luigi is in the big final fairing mode, and hopes to be launching in about half a year. His beams are somewhere out in the ocean at the moment. It was great to see the boat, and to be inside it etc. I really look forward to be able to sail one of these pretty things...

Here at 63° N it is back to work, not so much on the boat unfortunately due to the other one (that pays for all the fun stuff). But I managed to get all the HD inserts in, and hopefully enough bog to seal all foam junctions, during the week. Here the aft cockpit deck.

And the HD inserts for winch, sheet track, mast base and self tacking jib track.

I finally had a day off and thus made some real progress again today. Here is the finished cut fabric, peel ply and bleeder (I cut the release film as well, just doesn't show on this picture) for the aft cabin deck and cockpit coaming.

Obviously no pictures during the wet lay up and the vacuum bag installation, here the pump is working again. I did not dare to make the whole deck in one piece singlehanded, and it turned ot this was an excellent size lamination for one person.

Pulling out air and compressing the fabric towards the foam while excessive resin is being pushed out in the bleeder, making a superior quality laminate.

Then I finally got the UD carbon along the keel in. I did a mistake and forgot to get it in the big bag when we laminated the lower hull.

Then I finally got the UD carbon along the keel in. I did a mistake and forgot to get it in the big bag when we laminated the lower hull.

I didn't bother to bag it, just peel plyed it and it seemed to be working well. Less chance of bubbles when laminating over another layer of laminate as you don't have the air in the surface of the foam to struggle with.

I didn't bother to bag it, just peel plyed it and it seemed to be working well. Less chance of bubbles when laminating over another layer of laminate as you don't have the air in the surface of the foam to struggle with.

I am currently preparing the rest of the deck lamination, ie fairing bog joins. It is a bit complicated by the less than utimate access as you have to either hang in from the outside or slide down along the gunwhale on the inside, and then crawl back up for a new slide....

Then I had problems with the heater that would not start for a while, but after adding some of dr Alrons additive it seemed to be back on the track. Hope this works, because the climatic conditions here are not very epoxy laminating friendly at the moment.... I will spend the week end at work, but hopefully more progress next week.

And all of a sudden it is all contained in a bag, just after full vacuum is achieved. Actually, it is not at all so sudden, the resin has started to get quite sticky already:

And all of a sudden it is all contained in a bag, just after full vacuum is achieved. Actually, it is not at all so sudden, the resin has started to get quite sticky already: 2,5 hours later it is clearly visible, even with a blurry picture, that excessive resin has been soaked up in the bleeder fabric:

2,5 hours later it is clearly visible, even with a blurry picture, that excessive resin has been soaked up in the bleeder fabric: Then I put together these remedies to obtain the alignment points in order to make a correct placement of the aft beam bulkhead. This bulkhead is angled slightly relative to the form frames, and an exactly placement is crucial in order to achieve correct folding system alignment.

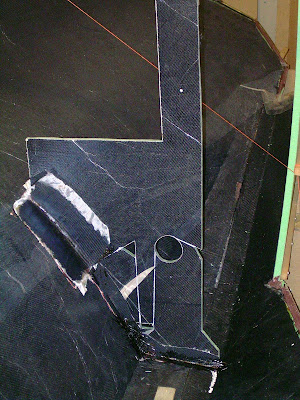

Then I put together these remedies to obtain the alignment points in order to make a correct placement of the aft beam bulkhead. This bulkhead is angled slightly relative to the form frames, and an exactly placement is crucial in order to achieve correct folding system alignment. Here it is, all taped in, in different views:

Here it is, all taped in, in different views: The lateral parts (below the white lines in this picture) of the bulkhead will later be removed and replaced by carbon fibre beam mounts made by Farrier Marine in NZ:

The lateral parts (below the white lines in this picture) of the bulkhead will later be removed and replaced by carbon fibre beam mounts made by Farrier Marine in NZ: